-

Next stop: energy efficiency

Next stop: energy efficiency

Energy efficient ventilation in the lift shaft

With the BlueKit AIO and BlueKit AIO Basic systems, you reduce energy costs and at the same time ensure safety and comfort in the lift shaft. The system combines efficient and needs-optimised ventilation with reliable smoke extraction.

BlueKit – the perfect interplay of reliable components

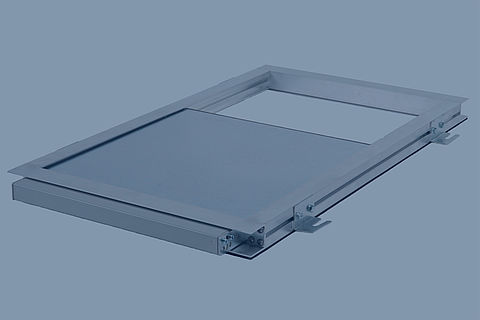

1 Ventilation flap (SHEV)

Function

Cutting back on energy losses thanks to closure of the opening in the lift shaft. Ventilates and extracts smoke when necessary.

Product details

- Depending on the building type, with or without weather protection

- For vertical or horizontal installation

2 Central unit

Function

Receiving and transmitting the trigger signal to open the ventilation flap.

Product details

Stand-alone central unit with integrated temperature sensor and extended connection options.

3 Smoke detection

Function

Smoke detection throughout the lift shaft height and signal transmission to the central unit.

Product details

- Two options: Point-type smoke detectors or infrared detectors (SD-L-F1)

- Choice dependent on shaft dimensions and building requirements

4 Lift Status Transmitter (LST-CO2)

Function

Monitoring air quality right in the lift car. Additional monitoring of movements or emergency situations in the lift. If needed, ventilation signal to the central unit.

Product details

- Integrated temperature sensor, CO2 sensor and acceleration sensor

- Time-controlled and use-dependent ventilation functions

- Temperature sensor on the car – now even more accurate

- Wireless radio link to the central unit

5 Manual trigger button with status display (optional)

Function

Manual triggering of a ventilation or smoke extraction command and system status display.

Product details

LED Status display depending on model option:

- Ventilation

- Fire alarm

- Malfunction

Reducing energy costs by closure of the permanent opening

Guarantee of safety for lift users thanks to reliable smoke detection and ventilation in emergency situations

Air quality improvement, reduction in humidity, odours and cold draught

Fewer servicing cycles and associated downtimes because of dust deposits in the lift door drive systems

Lower CO2 emissions and promotion of a sustainable building concept

BlueKit AIO Basic and BlueKit AIO in comparison The right system for every shaft

| BlueKit AIO Basic | BlueKit AIO | |

|---|---|---|

| Shaft properties | ||

| Shaft height (m) | up to 100* | up to 200 |

| Shaft type | Single and group shaft | Single and group shaft |

| System type | with and without machine room | with and without machine room |

| System components | ||

| smoke detector |

Point-type smoke detector (up to 36m) SD-L-F1 (up to 100m) |

Point-type smoke detector (up to 32m) RAS (up to 200m) Lift-Beam (8 up to 200m) |

| LST-VOC | ||

| Connection with manual buttons | up to 8 | up to 8 |

| System status display on button | Ventilation Fire alarm Malfunction |

Ventilation Fire alarm Malfunction |

| Manual release ventilation | ||

| Max. Number of NSHEVs | up to 2 |

up to 6 (spring return) up to 2 (direct current) |

| NSHEV ventilation area (m2) | 0,1 up to 1,2 | 0,1 up to 1,2 |

| NSHEV drive | Spring return motor | Spring return or direct current motor |

| Safety in case of power failure (opening of the ventilation component) | Spring return | Spring return or emergency battery |

| Safety in case of line and component malfunction | Fail-Safe | Fail-Safe |

| Connection options | ||

| Connection to lift control and fire alarm system | ||

| Connection to a smoke protection pressure system | ||

| Connection thermostat, siren, flashing light, etc. | ||

| Conformity | ||

| CE compliant components | ||

| Proof of function | ||

| Type of certification | VdS approval according to DIN EN 12101-10, ISO 21927-9 | VdS approval according to DIN EN 12101-10, ISO 21927-9 |

Get a tailor-made offer for your project.

We are happy to assist you in the planning of your project. Contact us.